21

A Guide to Core Drilling

Core drills are only used for enlarging diameters of existing holes

whether drilled, punched or cored. Having no point, the drill is only

able to cut on the chamfer. The maximum amount of material that

can be removed is restricted by the chamfer root diameter to 60%of

the core drill diameter.

Because of its multi-flute construction the core drill gives better hole

size and surface finish than a two flute drill. Two flute drills should

not be used to enlarge existing holes as they will tend to chip and

break.

Speed and Feed rates for Core Drills

Speed - As for 2 flute drills

Feed -

3 Flute

1 to 1,5 X 2 flute drill feed rate

4 Flute

1,5 to 2 X 2 flute drill feed rate

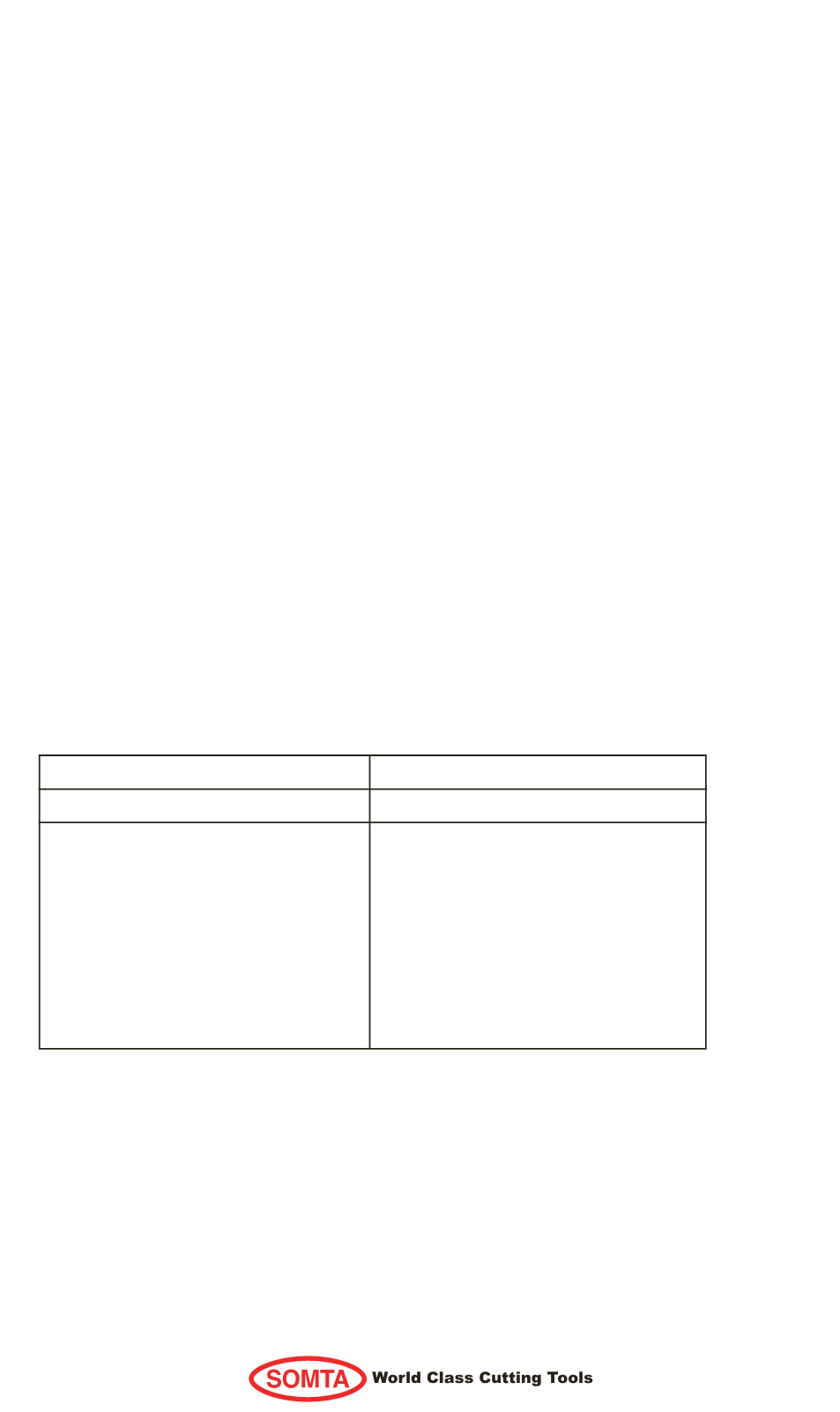

Cutting diameter tolerance

SOMTA Twist Drills are manufactured to h8 tolerance.

2 Flute Drills

Cutting Diameter Tolerance on Twist Drills

Drill Diameter (mm)

Diameter Tolerance (mm)

Above Up to

Plus Minus

- 3

+ 0 -0,014

3 6

+ 0 -0,018

6 10

+ 0 -0,022

10 18

+ 0 -0,027

18 30

+ 0 -0,033

30 50

+ 0 -0,039

50 80

+ 0 -0,046

Back Taper on Fluted Portion

The drill diameter is normally reduced over the fluted portion to

prevent jamming. The amount of back taper is a maximum of: 0,08

mm on diameter per 100 mm length.

Back taper is usually only applied to sizes over 6 mm.