19

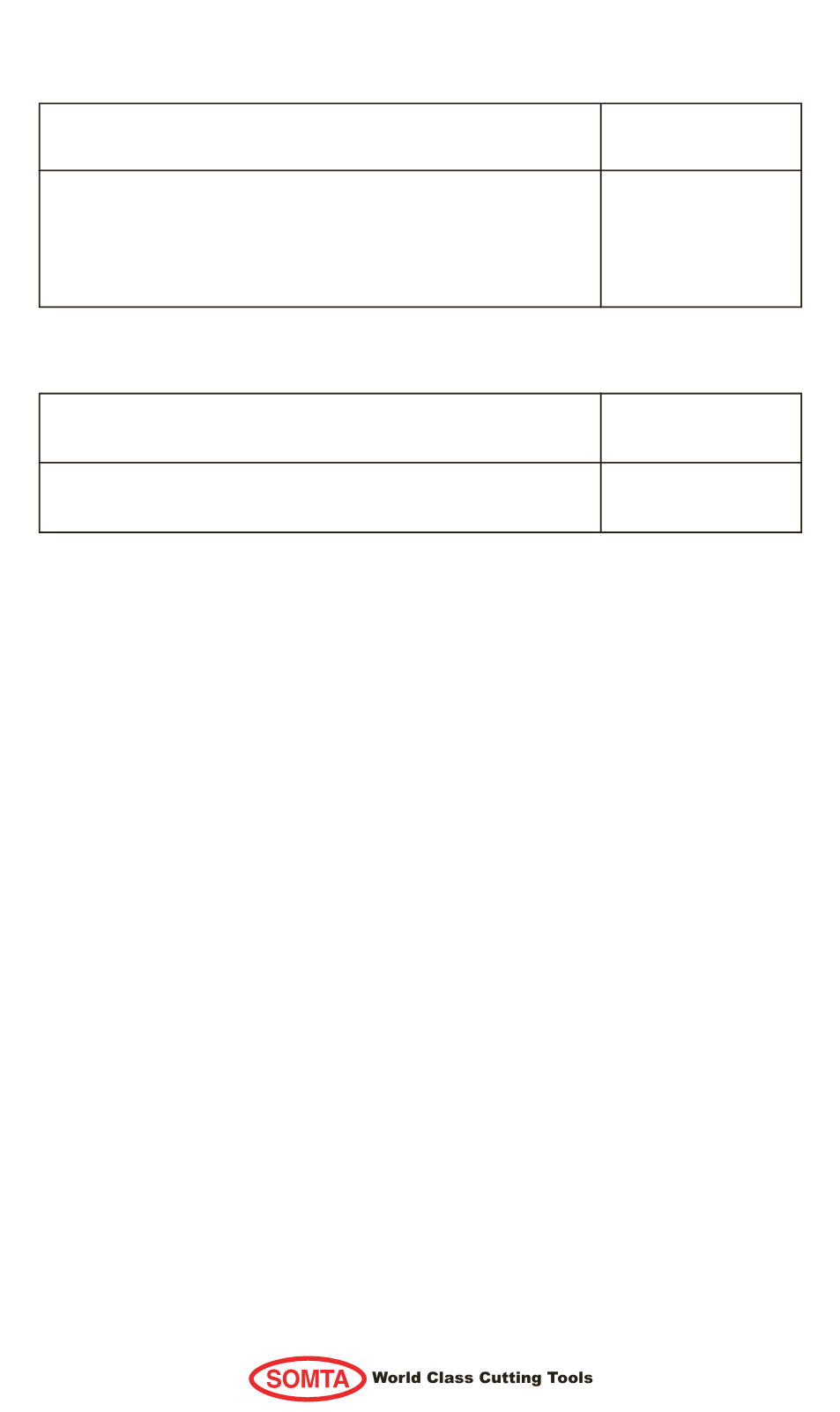

Recommended Speeds for Deep Holes

Depth of Hole

% Speed

Reduction

3 X Drill Diameter

10%

4 X Drill Diameter

20%

5 x Drill Diameter

30%

More than 6 X Drill Diameter

40%

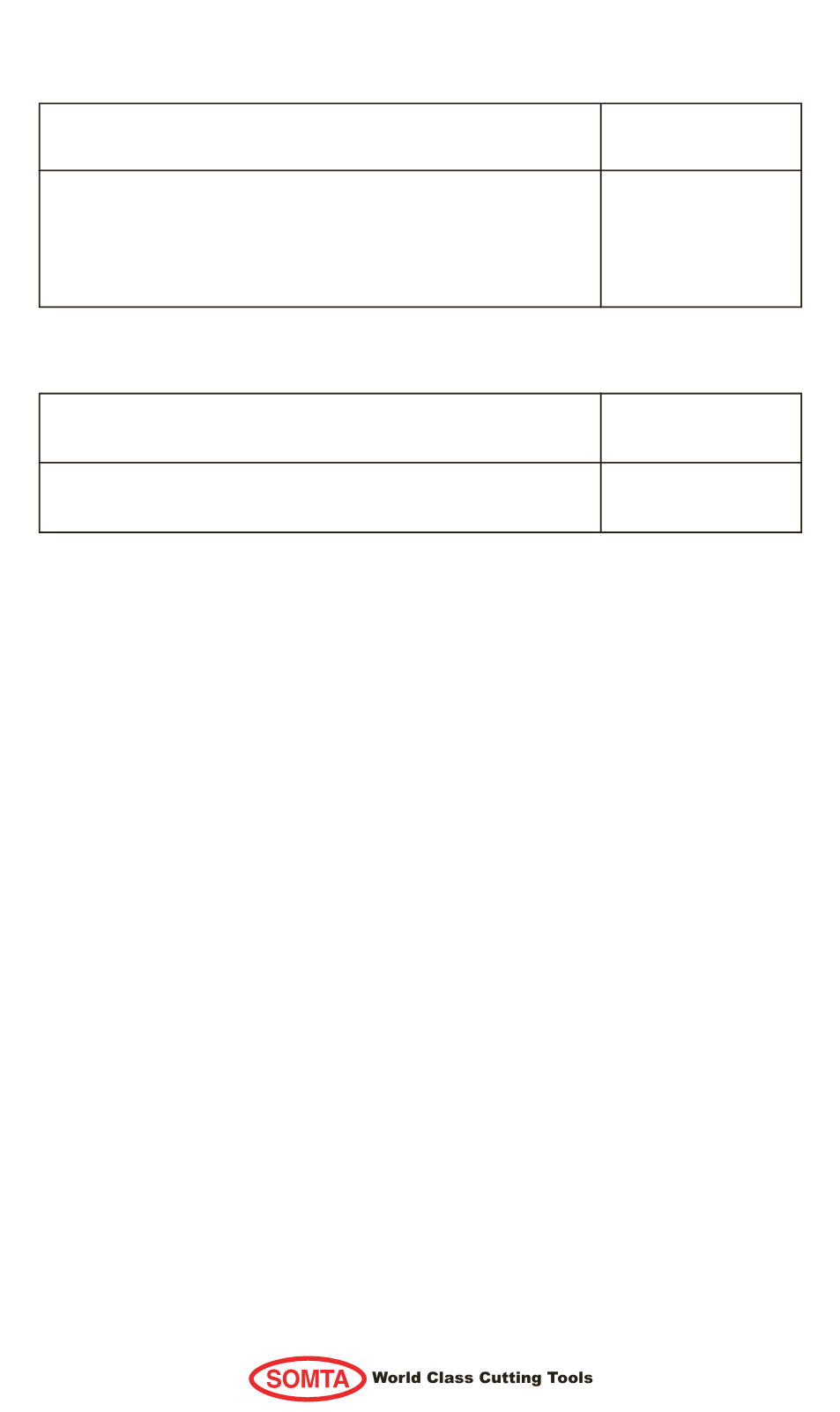

Recommended Feeds for Deep Holes

Depth of Hole

% Feed

Reduction

3 to 4 X Drill Diameter

10%

5 to 8 X Drill Diameter

20%

Extra Length "Deep Hole" Drills (UDL Form)

The SOMTA "Deep Hole" drill has a specially shaped flute form,

commonly known as Parabolic, which gives rigidity for deep hole

drilling and improves chip flow, enabling the full depth of the hole to

be drilled without withdrawal.

These drills are of special robust design for use on tougher materials

such as steels and cast irons with hardness up to 1000 N/mm².

Similar drills for softer materials such as aluminium, mild steel etc.

with hardness up to 500 N/mm² are available on special request.

Coolant Feed Drills

Higher production rates can be achieved when deep hole drilling by

using coolant feed drills.

Harmful heat generation at the drill point is prevented by the supply

of coolant to the cutting face. This allows higher speeds and feeds

and improved chip flow, thus eliminating the need to clear the flutes

by withdrawal.