61

NPT

Nominal

Diameter

Tapping

Drill Size (mm)

TPI

1/8

1/4

3/8

1/2

3/4

1"

1-1/4

1-1/2

2"

27

18

18

14

14

11-1/2

11-1/2

11-1/2

11-1/2

8.4

11.0

14.25

17.5

23.0

29.0

37.5

43.5

55.5

Fluteless Taps

Fluteless taps are used for cold forming threads in ductile materials

and have the following advantages.

(a) Increased strength and tap life resulting from:

(i)

Elimination of flutes which reduce the shear strength of

the tap.

(ii) The lack of cutting edges which, in a conventional tap,

wear and break down.

(iii) The lack of chips, which sometimes causes jamming.

(b) Better blind hole tapping due to the lack of chips and problems

relating to chip removal.

(c) Higher productivity due to faster tapping speeds.

(d) Stronger threads.

The grain fibres of the metal are not cut, but displaced, to form the

threads, which are stronger than cut threads. It is accepted that a

60% cold formed thread is as strong as a 75% cut thread.

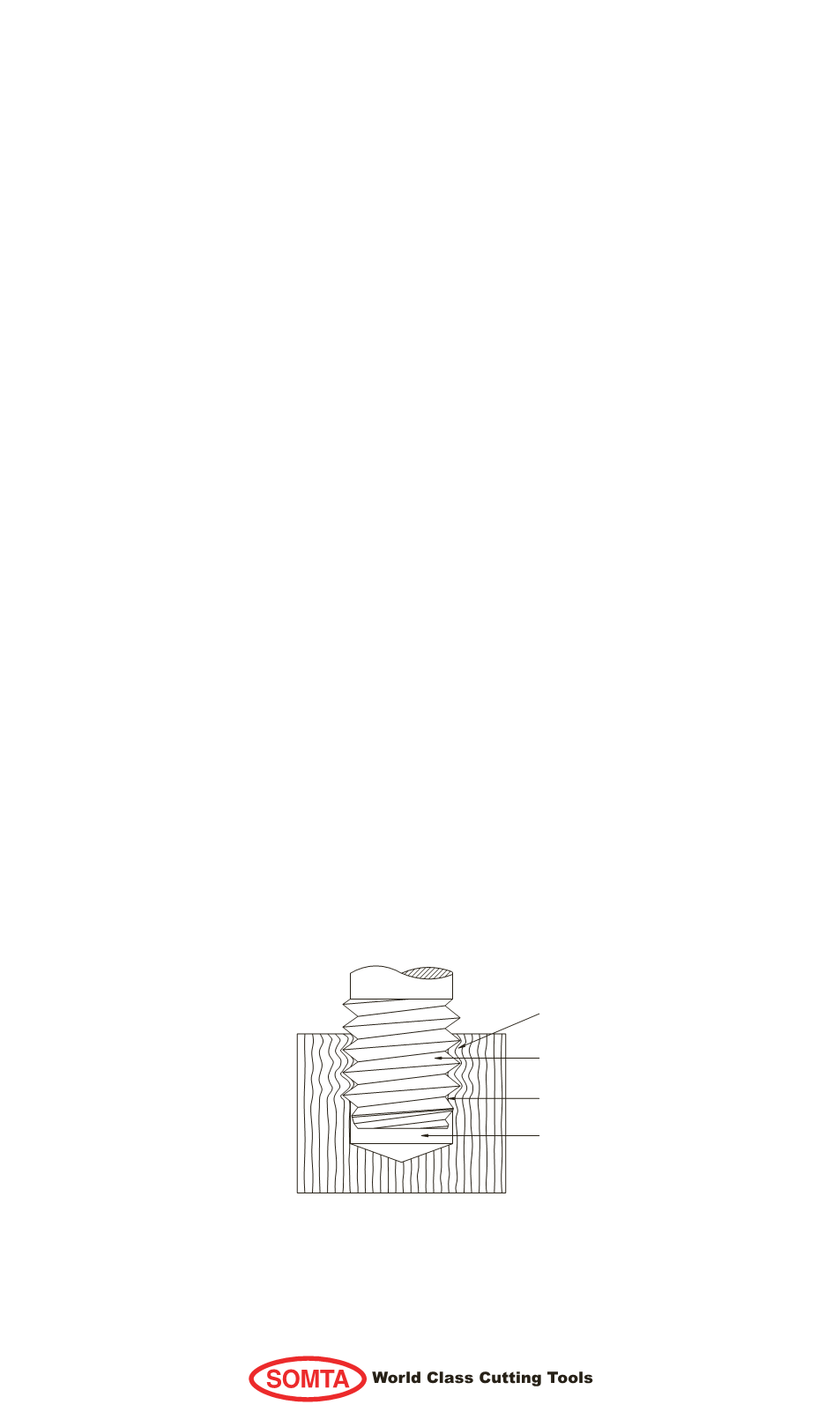

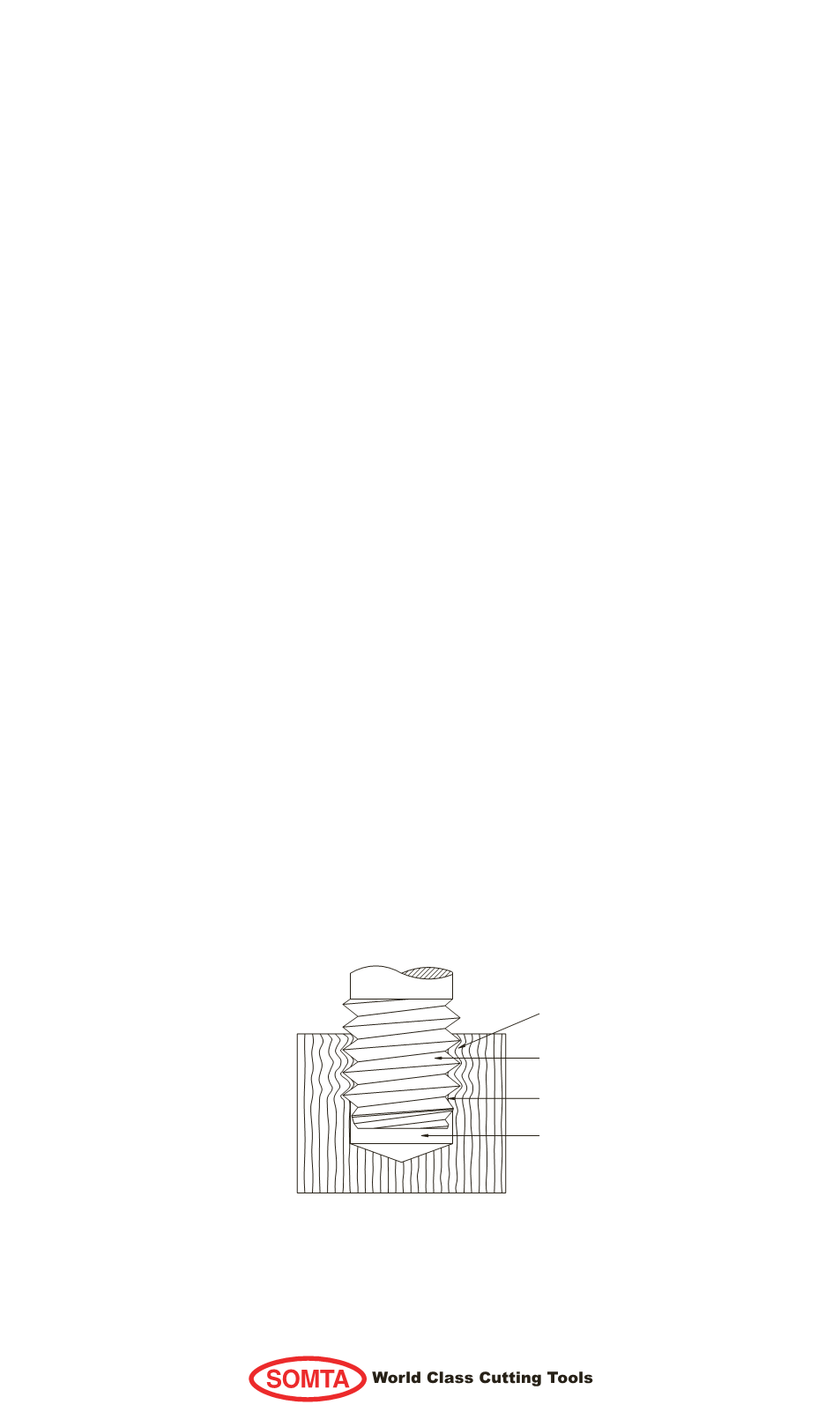

FLUTELESS TAP

STRONGER THREAD

GRAIN FIBRE OF

METAL UNBROKEN

BURNISHED THREAD

NO CHIPS