52

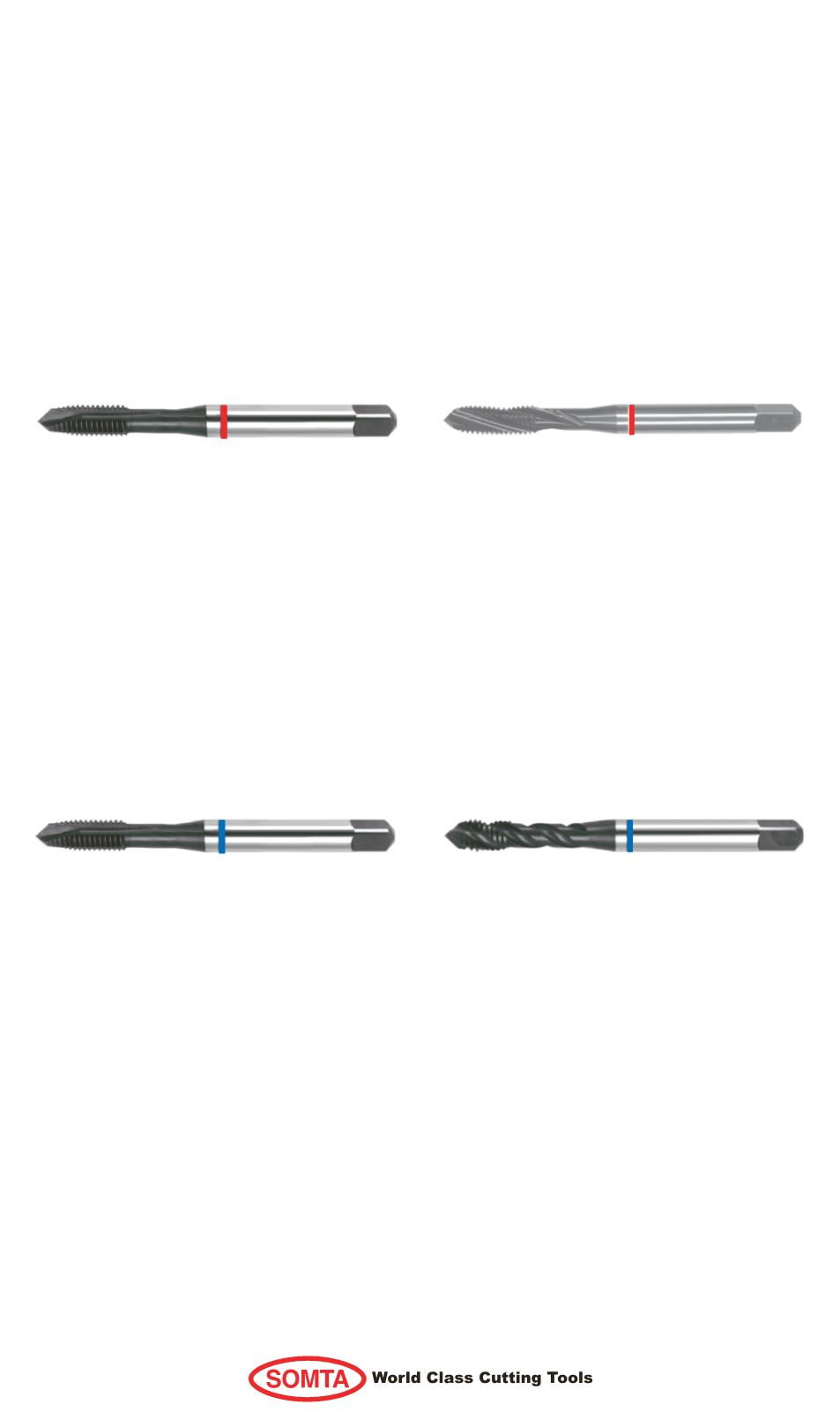

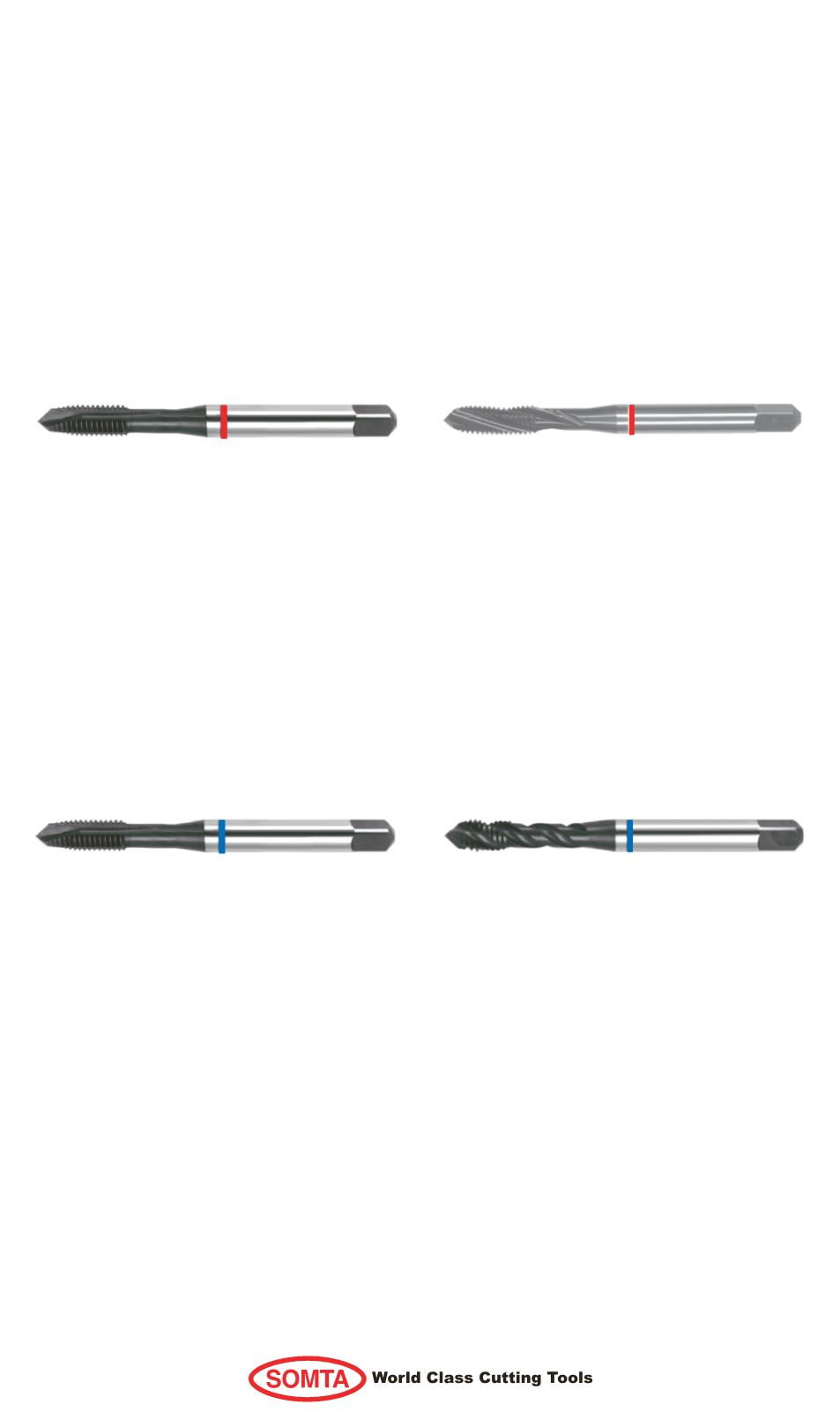

Colour Band Application Taps (CBA)

The primary benefit of the CBA range is enhanced threading

performance due to geometry designed for specific material

application groups. The result is an improved quality of finish and an

increased number of holes per tap, giving extended tap life and

reduced cost per hole. Manufactured from HSS-EV steel (High

Vanadium) for greater wear resistance.

Red Band

Designed for high tensile materials such as Tool Steels, Heat

Treatable Steels, Spring Steel, Case Hardening Steel, Unalloyed

Titanium, Nitriding Steel, Cold Drawn Constructional Steel and High

Tensile Steel.Used to tap materials with hardness up to 470HB,

tensile strength up to 1500N/mm². Spiral flute taps have 15° right

hand helix which efficiently forces high tensile material swarf up out

of the hole, while still maintaining correct cutting geometry. The red

band tap is supplied as standard with TiAlN coating.

Blue Band

Designed for tough materials, such as Stainless Steel, Titanium

Alloys, Cast Steel, Heat Resisting Steel and Work Hardening Steel.

Used to tap materials with hardness up to 350HB, tensile strength

up to 1250N/mm². Truncated thread after lead reduces frictional

contact with the threaded hole and allows easier penetration of

coolant. Spiral flute taps have 40° right hand helix allowing tough

material swarf to be efficiently removed from the hole. Supplied as

standard with TiAlN coating.