117

CLIMB OR CONVENTIONAL MILLING

From the very beginning of the milling process, it was found

practical to always rotate the end mill in the opposite direction to

the feed of the workpiece. This is termed conventional milling.

In conventional milling the end mill engages the workpiece at the

bottom of the cut. The end mill teeth slide along until sufficient

pressure builds up to break through the surface of the work.

This sliding action under pressure tends to abrade the periphery

of the end mill with resulting dulling. Also in horizontal conven-

tional milling, the cutting action has a tendency to lift the workpiece,

fixture and table from their bearings. In recent years, milling

machines have been greatly improved through backlash elimina-

tion and greater rigidity so that climb milling is now possible.

Climb milling improves surface finish and increases tool life.

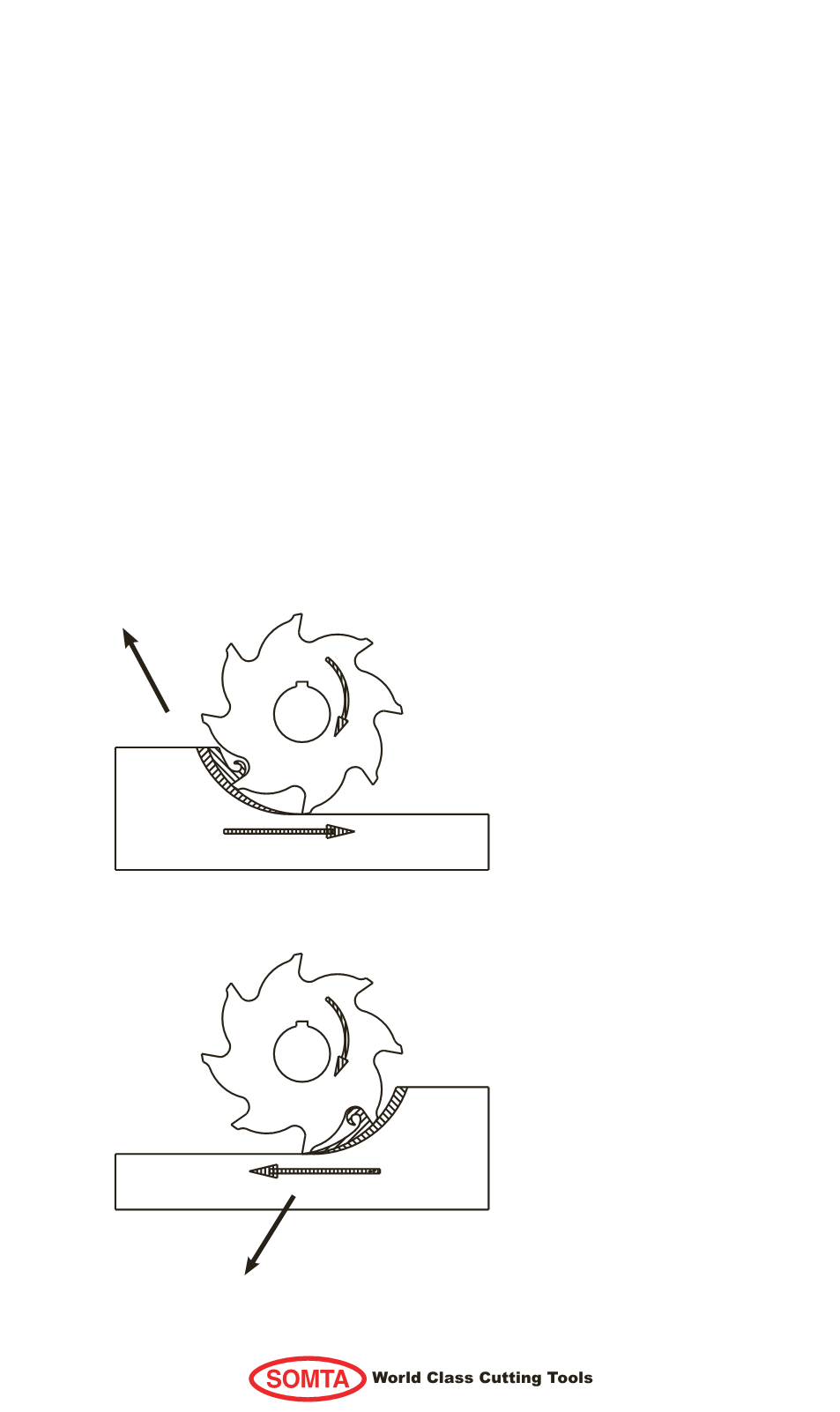

Conventional Milling

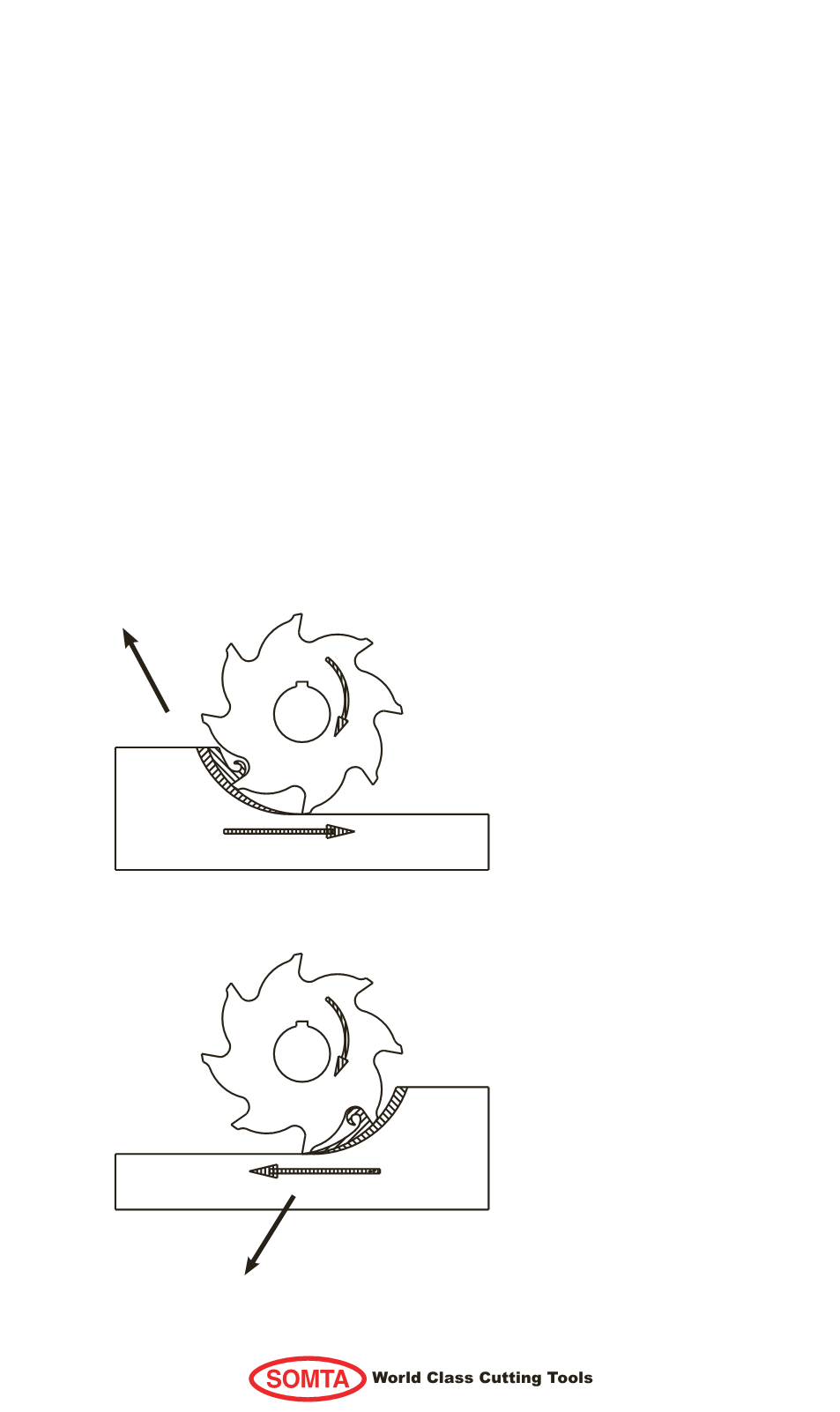

Climb Milling

Feed

Feed

Force

Force